Oil cylinders for press brake machines, also known as hydraulic cylinders, are one of the most important components of a press brake machine. They provide the power and control needed to bend metal sheets accurately and efficiently. Without oil cylinders, a press brake would not be able to generate the high force required for metal forming. Below is a clear and easy-to-understand explanation of what oil cylinders do and why they are so important.

1. Oil Cylinders For Press Brake Providing Bending Force

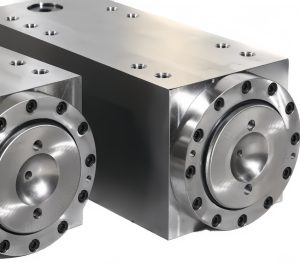

The main function of oil cylinders in a press brake is to generate bending force. When hydraulic oil is pumped into the cylinder, it pushes the piston downward. This movement drives the ram (or slide) of the press brake, which presses the upper punch into the metal sheet positioned on the lower die. Because hydraulic systems can produce very high pressure, oil cylinders allow the press brake to bend thick and hard metal materials with ease.

2. Ensuring Smooth and Stable Movement

Oil cylinders help the press brake move smoothly and steadily during operation. The controlled flow of hydraulic oil allows the ram to travel at a consistent speed, reducing vibration and sudden impacts. This smooth motion is essential for protecting the machine, tools, and workpiece. It also helps extend the service life of the press brake and improves overall operating safety.

3. Improving Bending Accuracy

Accuracy is critical in metal bending, and oil cylinders play a key role in achieving it. Modern press brakes use synchronized oil cylinders on both sides of the machine. These cylinders move together to keep the ram level during bending. This synchronization ensures even pressure across the entire length of the sheet, resulting in precise bending angles and consistent product quality.

4. Enabling Adjustable Pressure and Stroke

Oil cylinders allow operators to adjust both the bending pressure and the stroke length according to different materials and thicknesses. By controlling hydraulic pressure, the machine can apply exactly the right amount of force needed—no more, no less. This flexibility prevents overloading the machine and reduces wear on tools, while also making the press brake suitable for a wide range of bending tasks.

5. Supporting Advanced Control Systems

In CNC press brake machines, oil cylinders work closely with electronic control systems. Sensors monitor the position, speed, and pressure of the cylinders in real time. This data allows the control system to make precise adjustments during each bending cycle. As a result, oil cylinders help achieve high repeatability and automation, which is especially important for mass production.

6. Enhancing Safety and Reliability

Oil cylinders also contribute to machine safety. Hydraulic systems can include pressure relief valves and overload protection, which prevent damage if excessive force is applied. In addition, well-designed oil cylinders reduce mechanical stress and lower the risk of sudden failures, making the press brake safer and more reliable for daily use.

Conclusion

In summary, oil cylinders are the driving force behind a press brake machine. They provide the power, precision, and control needed for accurate metal bending. By ensuring smooth motion, adjustable pressure, high accuracy, and safe operation, oil cylinders play a vital role in the performance and reliability of modern press brake machines. Know more:https://www.hanzhimachinetools.com/oil-cylinder/